Superior cocoa quality based on community processing

Training, participatory risk analysis, the development of good practices and the design of solar dryers using photovoltaic panels predicts a rebirth for the cultivation of cocoa in the binational basin of the Sixaola River.

Context of the story

The Caribbean region in Costa Rica and Panama, where cocoa production is mostly based, is characterized by its vulnerability to extreme weather events, high levels of poverty and limited opportunities. Production declined in the past - despite the demands of high quality cocoa – due to diseases that devastated cocoa trees. The project takes place within this context, aimed at strengthening quality and productivity, in a framework of analysis and participatory work with all relevant actors. In essence, it seeks to boost the revival of cocoa cultivation and the quality of life of producing families.

Why does cocoa processing matters?

The implemented initiative

The project seeks to strengthen the livelihoods of families dedicated to the production of cocoa in the Caribbean region of Costa Rica and Panama and to reduce the vulnerability of these populations to extreme hydrometereological events. The optimization of fermentation and drying, which impact the final quality of cocoa, constitute the central axis of the initiative. Led by the National University of Costa Rica and supported by FONTAGRO, it had as main actors two organizations (APPTA and COCABO) which represent about 3000 producers.

Cocoa processing impacts on quality

The technological solution

In the cultivation of cocoa, productivity and quality must go hand-in-hand, both for market demands and for the need and expectation of producers to improve their living conditions. A good genetic base certainly contributes to quality, however, it is not enough to achieve it. Cocoa processing, in particular fermentation and drying, are as or more important than the genetic constitution of the plant in quality optimization.

The transport of freshly harvested cocoa for long hours and by rudimentary means decreases the total quality. Within this framework, the design of small-scale solar dryers that can allow fermentation and drying of cocoa in situ (particularly in communities far from central processing centers), contribute not only to the quality of the final product but also to the economy of the producer. The scaling of this technological solution can change for good the quality and profitability of the crop.

The drying system is capable of processing other agricultural products and generates excess electricity to enhance connectivity of producers.

Results

• Solar drying pilot systems were built with photovoltaic panels to minimize reported losses by up to 50%. Dryers can process 200 kg / week, enough for current and future productivity

• A state-of-the-art genomic analysis allowed the identification of more efficient organisms for fermentation

• Workshops were organized for the participatory analysis of risks and vulnerabilities in the face of possible extreme events or changes in the regional climate

• The project generated tasting and good practice guides as well as training to recognize sensory profiles and differentiate cocoa qualities

• The project activated a network of professionals, responsibile for the production, processing and commercialization of cocoa.

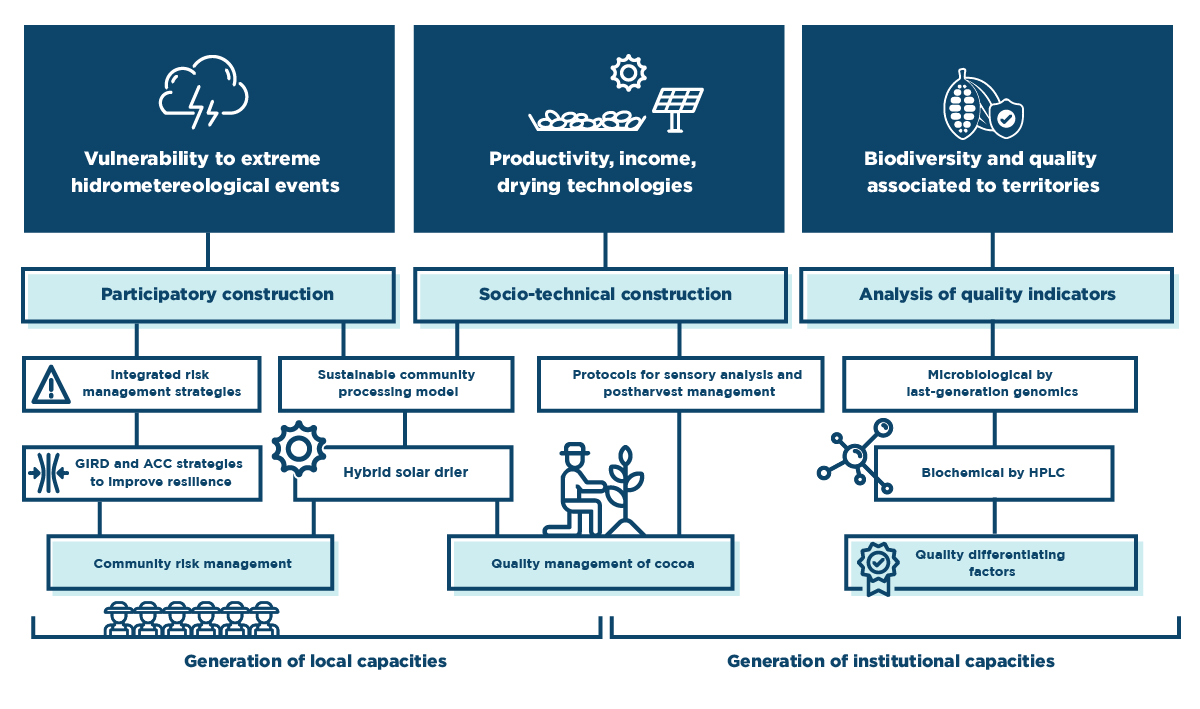

GRAPHIC SUMMARY

Project´s methodology

Back to the project

Back to the project Costa Rica

Costa Rica Panama

Panama